CTP冲版机显影机

CTP热敏版冲版机

Thermo-Sensitive CTP Plate Punching Machine

》产品介绍:

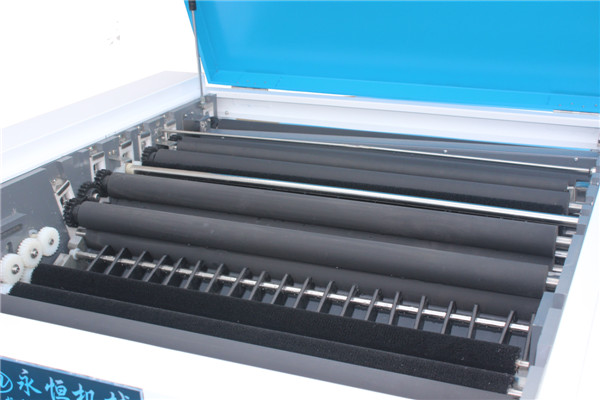

全电脑控制的热敏CTP版冲版机,自动完成显影、水洗、上胶、烘干等程序一次完成。超长显影过程和精确的温度控制,确保网点真实均匀再现。按照欧洲EC标准设计的,提供了所有的安全防护装置。工作宽度分别为85、120、130.140.厘米,可处理的版厚度从0.15到0.50毫米。在两个可变速旋转毛刷的协助下,通过浸没方式显影。显影槽由密封盖保护,密封盖位于和显影液接触的位置,从而避免了空气的氧化。通过版引导滑道形成显影液循环,保证显影液温度的一致而不造成液体波动。版引导滑道上的毛刷压力可以很容易调节。在版通道上的5对引导辊,进版速度可以调节,以保证速度为70厘米/分钟、30秒的浸没时间同时浸没深度为37厘米。和传统机器一样,CTP显影机也配备有环保系统:在显影工位的出口有两个辊积压版,从而防止显影液外溅带来的污染。在清洗工位有一个旋转毛刷,保证版的良好清洗效果。

保护胶装在单独的罐中,电脑调节送到位于版通道上喷嘴的保护胶数量。此系统避免了结块现象,以及由此带来的发臭可能,自动清洗上胶辊。

》性能特点:

▶超长显影过程加两只特殊毛刷,显影效果均匀、稳定、充分、彻底。特别适合感光快速的热敏版材。

▶精密显影液恒温系统,有效控制显影液温度,误差低于±0.5℃。

▶显影液循环系统,有效清除残渣,确保版面清洁。

▶全电脑控制所有参数及程序,精确可靠,版到喷水,版离停水。上胶胶辊自动清洗,防止胶水凝固,待机慢转,以防胶辊干固。

▶显影速度、毛刷转速、温度等参数数字化显示。

》规格型号及参数(特殊规格可定做)

Model and technical specification (Special specifications can be customized):

(见表格)

Product Introduction:

The computer controlled thermo-Sensitive CTP plate punching machine can automatically complete the process of developing, washing, gluing, drying and so on. The ultra long developing process and accurate temperature control ensure the true and uniform reproduction of the dot. According to the European EC standard, all the safety protection devices are provided. The working widths are 85, 120 and 130.140. cm, respectively. The thickness of the treated plates ranges from 0.15 to 0.50 millimeters. With the aid of two variable speed rotating brushes, the immersion method is developed. The developing tank is protected by a sealing cover, and the sealing cover is positioned at the contact point with the developer so as to avoid the oxidation of the air. The developer guides the slideway to form the developer circulation, so as to ensure the consistency of the developer temperature without causing liquid fluctuation. The brush pressure on the guide slide can be easily adjusted. The 5 pairs of guide rolls on the plate channel can be adjusted to ensure that the speed is 70 cm / min, 30 seconds immersion time, and the immersion depth is 37 cm. Like traditional machines, CTP development machines are equipped with environmental protection systems: there are two roll backlog versions at the exit of the development station to prevent contamination from splash of the developer. There is a rotary brush in the cleaning station to ensure the good cleaning effect of the plate.

The protective adhesive is packed in a separate tank and the computer adjusts the amount of protective glue to the nozzle on the plate channel. This system avoids caking phenomenon and the possible odor, and automatically washes the top roller.

Performance Characteristics :

·Super long developing process with two special brushes, the developing effect is even, stable, full and thorough. It is especially suitable for fast thermal sensitive plates.

·The precision developer temperature control system can effectively control the temperature of developer solution, and the error is less than or equal to 0.5 degrees centigrade.

·The developer circulation system, effectively remove the residue, ensure the layout clean.

·Full computer control all parameters and procedures, accurate and reliable, plate to water, plate without water. The rubber roller is cleaned automatically to prevent the solidification of the glue, and to slow down the standby, so as to prevent the cots from being dry and solid.

·Digital display of development speed, brush speed, temperature and other parameters.

| 机型 Model | CTP-880型 | CTP-1200型 |

| 进版尺寸 Plate Size | 350mm-880mm | 350mm-1200mm |

| 印刷厚度 Plate Thickness | 0.15mm-0.4mm | 0.15mm-0.4mm |

| 显影速度 Dev. Speed | 20-60s | 20-60s |

| 显影液容量 Developer Capacity | 20L | 25L |

| 烘干温度 Drying Temperature | 30-60℃ | 30-60℃ |

| 显影温度 Dev. Temperature | 15℃-40℃ | 15℃-40℃ |

| 电源电压 Power Supply | 单相220V/50Hz 30A | 单相220V/50Hz 30A |

| 净重 Net Weight | 380Kg | 560Kg |

| 外形尺寸 Outside Dimension | 2520×980×1000mm | 2520×1180×1000mm |

相关产品

相关新闻

- 泰兴市永恒机械制造厂提前祝您春节快乐!

- 关于印刷废水处理设备的适用范围和特点是什么?

- 印刷废气处理净化设备的简单介绍

- 在润版液的选择上有什么要求