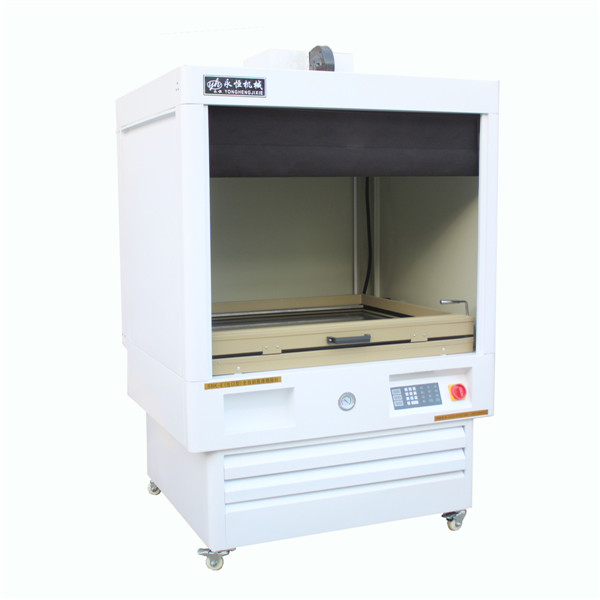

全自动收版台

Full-automatic Receiving Platform

》产品介绍:

全自动收版架完全依照国际规格的设计要求,在前端感应器感应到冲版机所传出了PS版后随即启动向下的传动马达,当PS版抵达下端定位后,再由感应器启动翻版马达,将PS版送上集版架。整个过程完全自动化,取代了传统的人工收版过程,实现了人力的解放,同时也避免了PS版的人为磨损和浪费。

》性能特点:

·采用多感应器系统,高灵敏度的感应器带来高效的生产率。

·翻版过程进行中如遇人为阻碍会自动停止一切操作并发出警号信号。

·与冲版机匹配使用,与常规的冲版机匹配度高。

·全系列符合欧洲生产规格要求及安全规范。

Product Introduction:

Full-automatic receiving platform completely according to the international standard design requirements, in front of the sensor induction to the plate machine came out after the PS version, then start the downward drive motor, when the PS version arrived at the lower end positioning, and then start the copying motor by the sensor, the PS version sent to the set plate frame. The whole process is completely automatic, instead of the traditional manual printing process, the liberation of manpower, but also avoid the PS version of man-made wear and waste.

Performance Characteristics:

·Using a multi sensor system, high sensitivity sensors bring high productivity.

·And in the case of replica process of man-made obstacles will automatically stop all operations and send alarm signal.

·Matching with punching machine, it has a high matching degree with conventional punching machine.

·The full range meets European production specifications and safety standards.

- 印刷废水处理设备怎么处理印刷废水呢

- 润版液净化装置生产企业哪家更受欢迎

- 印刷废水处理设备活性污泥培菌方案

- 印刷废气处理设备之活性炭吸附塔